The Lots Of Usages of Aluminum Castings: A Comprehensive Overview for Market Professionals

Aluminum castings play an important function across numerous sectors, many thanks to their special buildings. These resilient and lightweight elements are vital in auto and aerospace applications. Comprehending their advantages and the production processes included can considerably affect performance and efficiency. As innovation advances, new advancements proceed to arise. Sector specialists have to consider these elements to make educated choices. The implications of these advancements deserve exploring additionally.

Benefits of Light Weight Aluminum Castings in Different Industries

Aluminum spreadings use countless advantages throughout various sectors, making them a preferred choice for numerous applications. One of the main benefits is their lightweight nature, which adds to overall energy performance in transportation and machinery. This lowered weight likewise enhances ease of taking care of and installment, leading to lower labor expenses.

Additionally, aluminum castings display excellent corrosion resistance, expanding the life expectancy of components in harsh atmospheres. Their thermal and electrical conductivity enables effective warm dissipation and efficient electrical applications.

Furthermore, light weight aluminum can be conveniently alloyed and manipulated, enabling the production of complex forms and layouts that fulfill particular design requirements. This adaptability sustains technology in sectors such as automobile, aerospace, and consumer items.

The recyclability of light weight aluminum lines up with lasting practices, making it an eco friendly alternative for modern manufacturing. Generally, the advantages of light weight aluminum castings position them as crucial materials in various industries.

Trick Manufacturing Processes for Light Weight Aluminum Castings

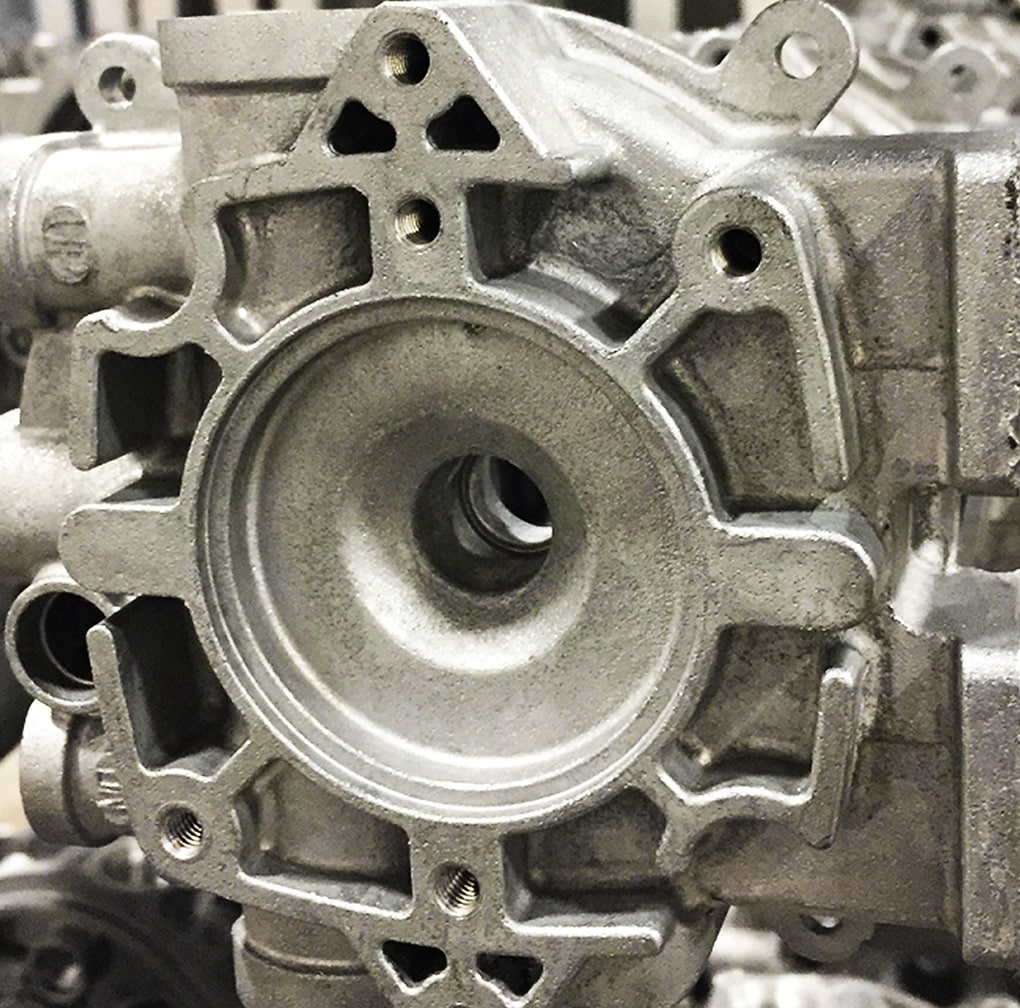

A variety of producing processes are used to create aluminum castings, each tailored to satisfy certain application needs and manufacturing volumes. Amongst the most usual methods are sand spreading, pass away spreading, and investment spreading.

Financial investment spreading, additionally referred to as lost-wax casting, gives extraordinary surface area finishes and intricate details, commonly made use of for smaller sized, precision parts. Furthermore, gravity spreading utilizes the pressure of gravity to fill molds, suitable for bigger castings where accuracy is much less critical. Each procedure has its advantages, satisfying varied commercial requirements while optimizing performance and top quality in aluminum casting manufacturing.

Applications of Light Weight Aluminum Castings in Automotive and Aerospace

In various applications within the aerospace and automotive markets, aluminum castings play an important duty because of their light-weight residential or commercial properties and exceptional strength-to-weight ratio. In the vehicle market, components such as engine blocks, transmission situations, and wheel edges are often created utilizing light weight aluminum spreadings. These components profit from reduced weight, resulting in improved gas performance and boosted efficiency.

In aerospace, light weight aluminum castings are necessary for structural components, including airplane frames, touchdown gear, go to my site and engine housings. The material's resistance to deterioration and capacity to withstand high temperature levels make it excellent for these requiring applications. In addition, light weight aluminum spreadings help with complex geometries, enabling the style of complex components that add to total aircraft effectiveness.

Innovations and Advancements in Aluminum Casting Technology

As industries remain to develop, developments in aluminum casting innovation are driving significant renovations in efficiency and performance. Advanced techniques such as 3D printing and casting simulation software program have changed traditional methods, permitting more specific styles and lowered waste. These innovations make it possible for producers to develop intricate geometries that were formerly unattainable, enhancing the convenience of aluminum castings.

Additionally, the development of new alloy structures and treatment techniques has actually enhanced mechanical residential properties, making spreadings lighter yet stronger. Automated processes are likewise being integrated, decreasing human error and enhancing manufacturing speed.

Finest Practices for Making Use Of and choosing Light weight aluminum Castings

When selecting and using light weight aluminum spreadings, mindful factor to consider of particular requirements can considerably affect the end product's performance and longevity. Industry experts should assess the certain application needs, including load-bearing abilities, deterioration resistance, and thermal conductivity. Choosing the proper alloy is vital, as different alloys use varying toughness and characteristics.

Additionally, recognizing the casting process-- whether sand casting, die casting, or investment spreading-- will affect the final item's high quality and cost-effectiveness. Quality control measures, such as non-destructive screening and dimensional inspections, are necessary to assure that the castings meet market requirements.

Moreover, appropriate handling and storage of aluminum spreadings can avoid damage, guaranteeing peak efficiency. Ultimately, collaborating with credible suppliers that prioritize quality assurance can enhance the integrity of the ended up parts. By sticking to these finest practices, industry professionals can take full advantage of the benefits of light weight aluminum castings in their applications.

Regularly Asked Questions

What Are the Ecological Impacts of Light Weight Aluminum Casting Production?

Light weight aluminum spreading production can cause substantial environmental impacts, consisting of greenhouse gas discharges, power intake, and source exhaustion. Additionally, improper waste administration might lead to dirt and water contamination, influencing local ecosystems and areas.

Just How Do Aluminum Castings Contrast to Other Steel Spreadings?

Light weight aluminum castings are lighter and corrosion-resistant contrasted to various other metal castings like iron or steel. They supply exceptional thermal and electric conductivity, making them optimal for applications where weight and sturdiness are essential elements.

What Is the Price Difference Between Aluminum and Other Products?

The price of light weight aluminum castings typically varies from modest to high, often more affordable than stainless-steel however costlier than some plastic options. Metal Castings. Elements such as production quantity, complexity, and product specifications substantially influence overall prices

Can Light Weight Aluminum Castings Be Reused?

Light weight aluminum spreadings can indeed be reused. This procedure significantly decreases power usage and environmental impact contrasted to generating new light weight aluminum, making recycling a crucial technique in advertising sustainability and source preservation within numerous markets.

What Safety Procedures Should Be Taken During Aluminum Spreading Processes?

Throughout aluminum spreading processes, crucial precaution include using safety gear, making certain correct air flow, making use of heat-resistant devices, maintaining equipment, and adhering to safety methods to avoid direct exposure to harmful materials and decrease the threat of accidents. (Aluminum Castings)

Sand casting involves developing a mold from sand, enabling for huge castings and complicated shapes. Investment spreading, likewise recognized as lost-wax spreading, gives exceptional surface area finishes and elaborate details, commonly made use of for smaller, accuracy parts. In addition, gravity spreading utilizes the force of gravity to fill mold and mildews, ideal for larger castings where accuracy is less vital. In addition, understanding the spreading procedure-- whether sand spreading, die casting, or financial investment spreading-- will influence the last product's top quality and cost-effectiveness. Aluminum castings are lighter and corrosion-resistant contrasted linked here to various other steel castings like iron or steel.